Let's start!

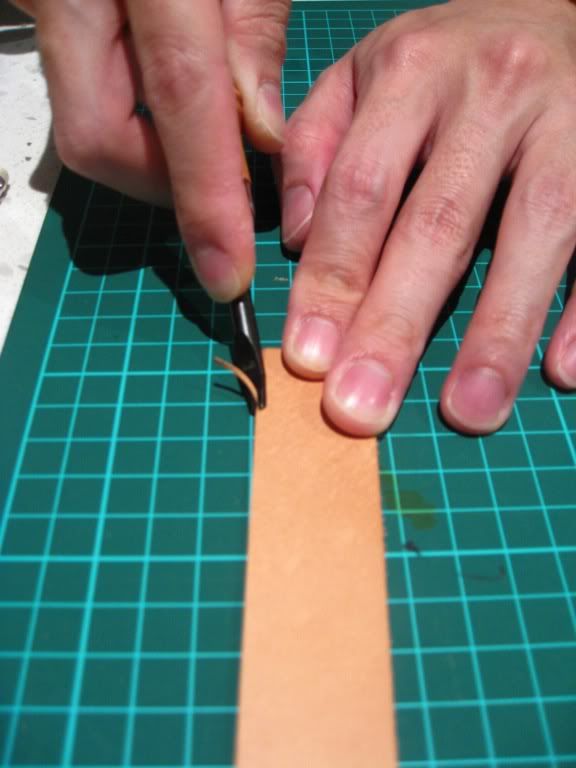

Start with shorter 26mm piece, which should be cut together in part 1.

Bevel the edge using 'edge beveler'.

Burnish the leather and apply beeswax.

Test fold the leather first to determine point of contact for the overlap part.

Once done, mark with pencil and start skiving.

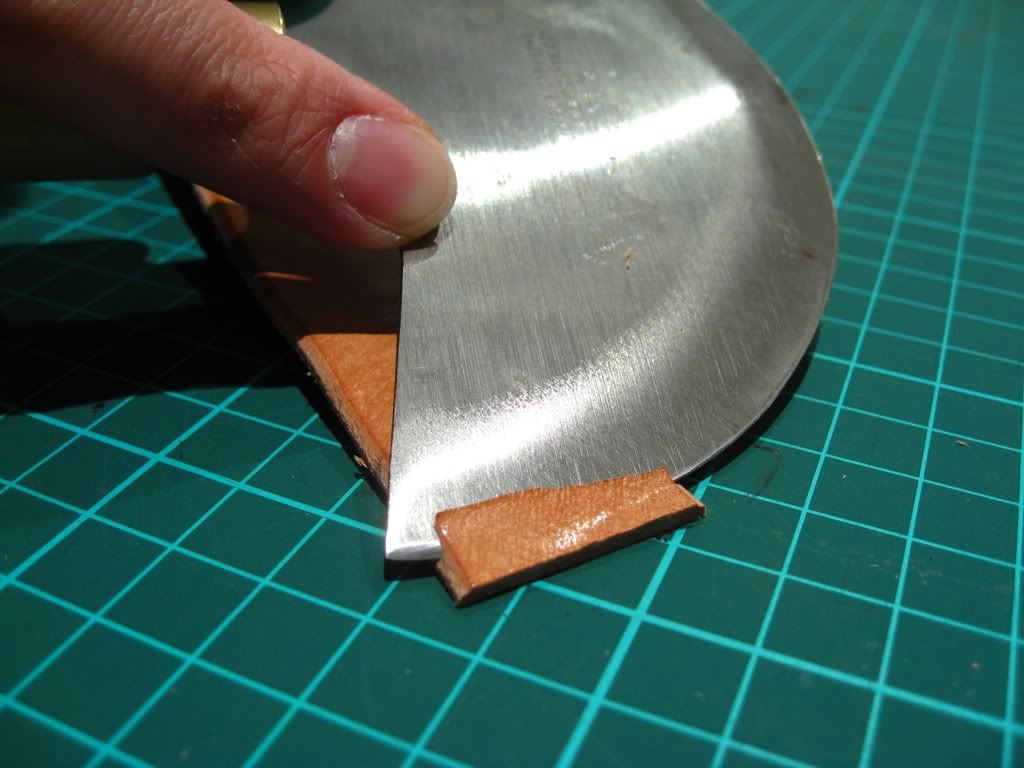

Start with the buckle side, skive the grain part.

Now skive the flesh side of the other part that will overlap.

Slightly wet the flesh side to mark the punch hole for the buckle tongue (I use oblong punch) and

measured with ruler to ensure it's even from both side.

Start punching the hole.

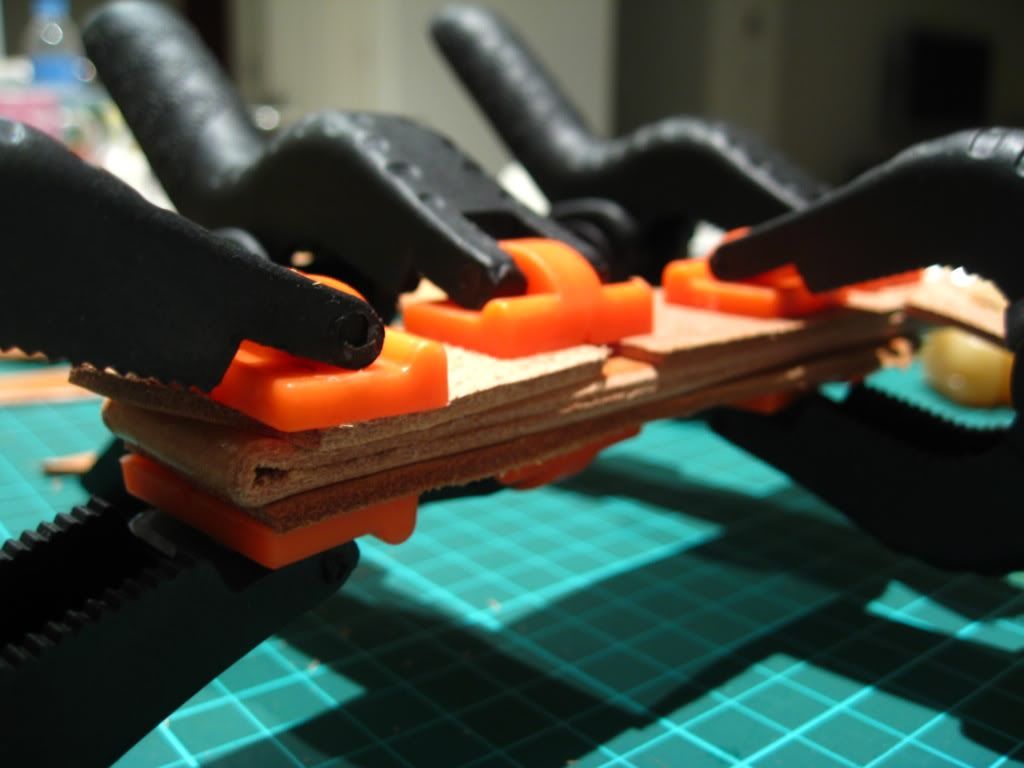

I prefer to glue the folds in two part rather than all at once to ensure consistency.

Glue the buckle side first, use clamp to secure, wait for few hours until glue has dried.

Once the buckle part has dried, thin/skive the part where the leather is to be folded to ensure good usability (I only do the lug side).

Now the other part is ready to be glued, secured with clamp, leave overnight to dry.

Once dried, smooth the edges using sanding block.

Using creasing tool, create parallel lines for stitching purpose.

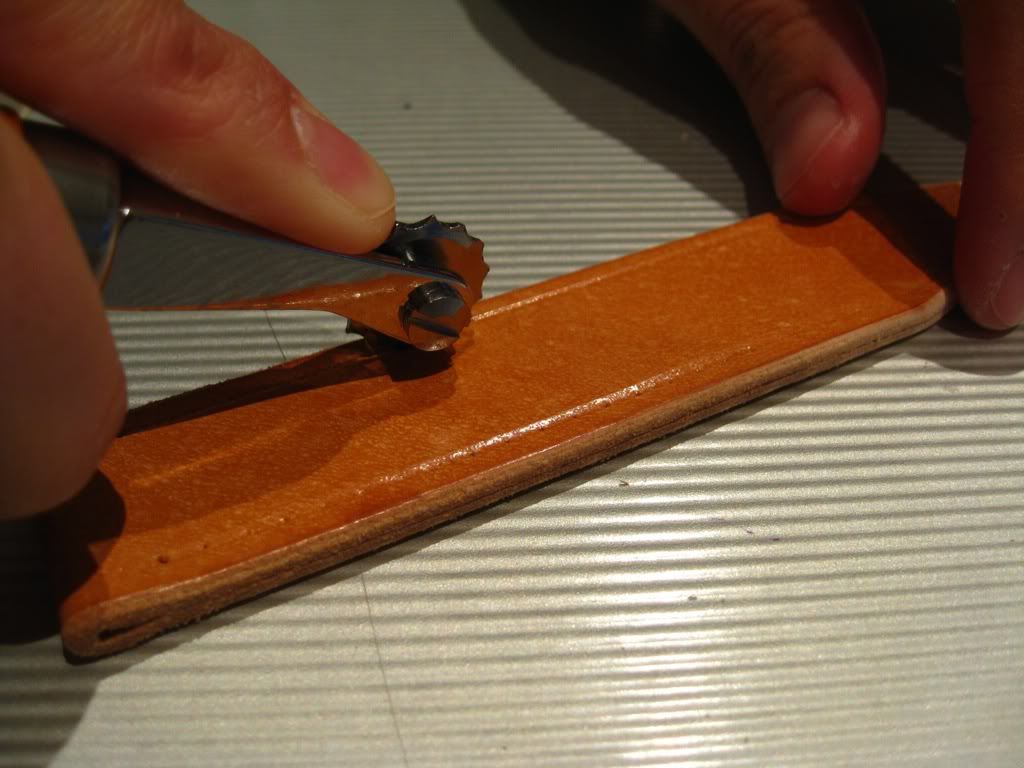

Mark the first stitching holes using an awl, then create more using stitching wheels.

Punch the stitching holes.

The edge is ready to be burnish, apply two coat of gum tragacanth (first layer to dry, second slightly dry), then rub friskily with slicking wheel resulting in slick smooth edge.

Optional step: apply clear sealer to preserve the edge further.

Now let's make the keeper!

I use the exact same leather to ensure similar texture and colour, the thickness will also be a perfect match.

First step is to measure how long the leather piece should be, do this by stacking two completed strap on top of each other and run the leather strip around. Try to underestimate as loose keeper looks undesirable, it should be a snug fit (sorry forgot to take photo of this step).

Once done, cut the leather to size then case it or wet the leather.

Whilst the leather is still damp, run a creaser tool to make a line impression. The impression will remain once the leather has dried.

Rub the leather with a piece of canvas to burnish it.

Apply two layer of gum to the edge and rub friskily using slicking wheel.

Mark the holes for stitching using an awl. By pressing the awl harder, hole can be made. Stitch two part together.

I applied gum into the flesh side of the keeper to seal it so the strap can glide easier. I also apply sealer to the edge to preserve it.

What's left now is to punch the buckle holes.

Use a ruler to ensure evenness (again, I apologise, no photo was taken). Once holes is punched, seal it with a cotton bud soak with sealer solution and burnish them with the punch tool (top and bottom side). This will add to the durability of the strap.

Final words, the tutorial can be apply to other types of leather, but the process will vary. Use this as a guide not as a definitive process. This is only one way of making a watch strap, there are hundreds of other ways of building a watch strap which might suit your style better. My best advise is to find your own style and do things in accordance to your own skill.

Having the correct tool greatly help the process and avoid frustration down the road. Persistent is the key when working with leather, it takes 10 days to learn everything about the leather but takes 10 years to truly master it. I'm on my third year and still learn a great deal about leather every day.

This concludes the strap making tutorial. I hope this will help someone in their quest working with leather. Please feel free to leave a comment or two to make this tutorial better.